According to the theory of constraints (TOC), an organization’s capacity to accomplish its most vital objectives at any given time is limited by the presence of only one constraint. In addition, you can use the theory’s tools to figure out what’s holding you back and devise a strategy to conquer it. When seen through the viewpoint of subject matter specialists, the TOC becomes more clear:

Since the flow is the priority, it takes time and effort to successfully move through each stage of any process. On the other hand, strategy may lead if a process or system is highly complex. Nonetheless, TOC is about making your processes more effective so that your organization can achieve its goals. Also, consider how TOC can help you uncover straightforward solutions to challenging issues.

TOC History

The theory of constraints was first established in 1984 in Dr. Eliyahu M. Goldratt’s best-selling business novel “The Goal.” The Theory of Constraints Institute was founded after Eli’s death to celebrate his legacy. This TOC timeline highlights critical periods in the movement’s development.

Dr. Goldratt earned a bachelor’s degree from Tel Aviv University, a master’s degree from Bar-Ilan University, and a Ph.D. from the Hebrew University of Jerusalem. This firm foundation in physics and exact sciences that he had laid for himself greatly impacted his work and worldview throughout his life.

After working with several Israeli enterprises, Goldratt left academia to found Creative Output. The company developed and marketed the Optimized Production Technology software suite (OPT). OPT is widely considered the first scheduling application explicitly designed to manage production scenarios characterized by constrained capacity. Numerous significant studies examined this program and the underlying concepts, which helped lay the groundwork for the theory of constraints.

Start With Where You Focus Your Attention

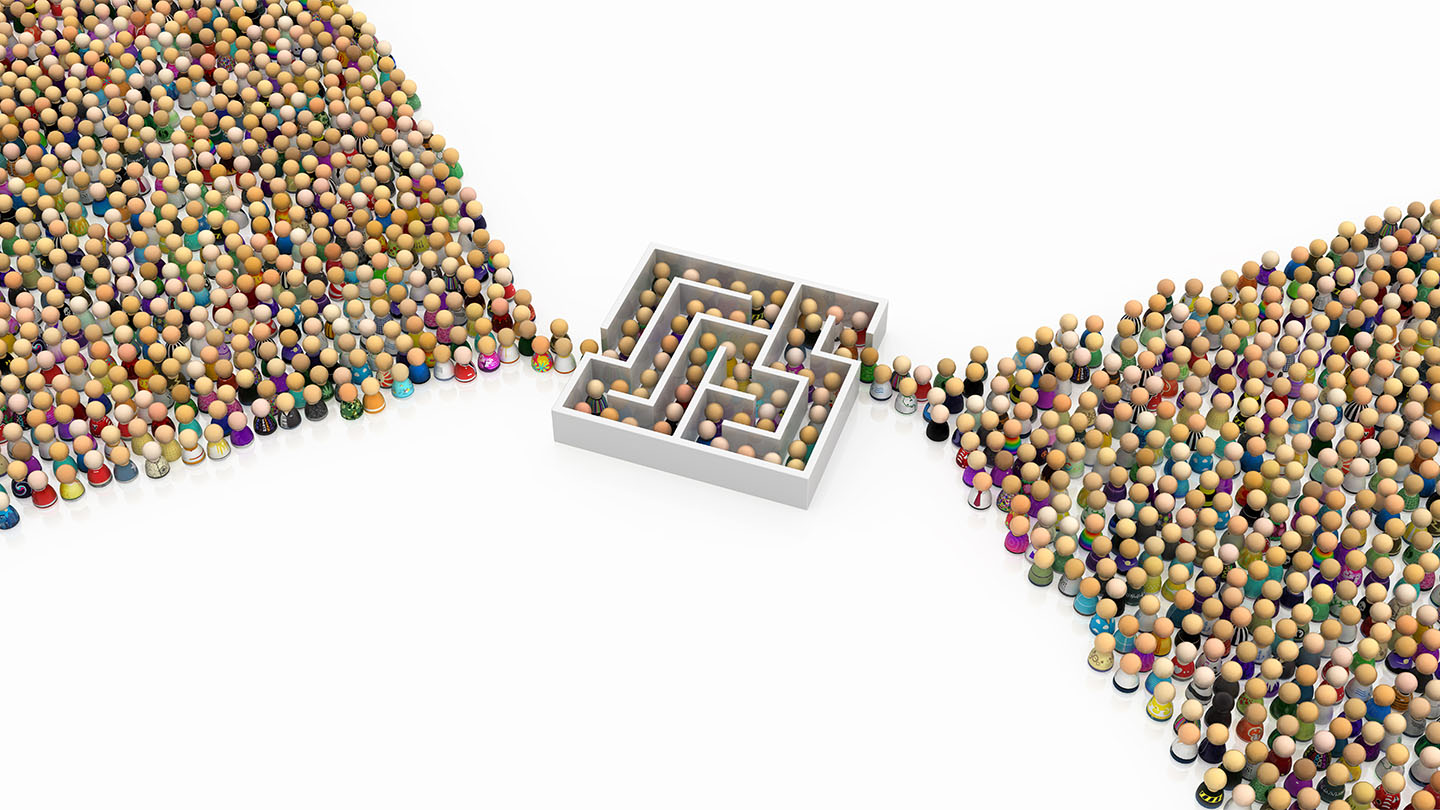

You may zoom in on a particular procedure or step before panning out to examine the entire line or process using the theory of constraints. TOC considers corporations to be networks of functions and divisions rather than separate entities. For instance, find the weakest link. As the TOC refers to it, you will achieve your goal if you identify and concentrate on the weak link or constraint.

Individual or local production within a product line or organization may be viewed in a new light due to TOC. People and departments who excel at completing tasks fast and producing a considerable volume of goods may not be valuable to the rest of the organization. According to TOC, the primary role of a business is to generate revenue or, in the case of a service organization, to give value to consumers. A TOC company’s objective is to generate money through sales rather than create a product. In TOC, this is referred to as throughput.

Instruments and Methods

The theory of constraints seeks to address three fundamental difficulties by offering a goal and a method for problem resolution.

- What should I do next?

- What can I use in its place?

- How can we fix this to make it right?

The Five Steps

TOC has a slew of utilities that aren’t found anywhere else. They can assist your organization in focusing on its purpose by providing structure and consistency in the analysis and resolution of difficulties. As examples, consider the following:

- Identify: Determine what impedes your progress and take steps to correct it (the single part of the process that limits the rate at which the goal is achieved).

- Exploit: Utilize current resources to enhance the constraint’s throughput quickly.

- Subordinate: All future methods must adhere to and support the restrictions.

- Elevate: Consider what further steps may be adopted to overcome the constraint.

- Repeat: This method is frequently repeated once the restriction has been “broken” (until it has moved somewhere else). It is not commonplace to be asked to make an initial financial commitment.

The usage of the Five Focusing Steps is an ongoing educational process. As a result, once one barrier has been overcome, it is critical to complete the next as soon as possible. Focus on the current constraint first to prevent becoming used to a new one.

However, the most challenging component is getting past the “Drum.” The “beat” of the constraint impacts the process’s overall throughput.

What can help? A “buffer” is required to maintain a constant flow of output. The restriction is unaffected by non-constraint occurrences such as pauses and fluctuations. Work-in-progress should be accessible for a set period before being used, ensuring that the protected resource is always available. During this period, the most frequent unit of measurement is the hour.

As a result, the greater the number of buffers, the more irregular the process. Planned overcapacity is a more cost-effective alternative to enormous buffer stocks with no constraints.

- Two buffers are always used: One for input and one for output.

- Acting as a buffer between the constraint and the constraint protects the constraint.

- Project is completed on schedule.

- The “Rope,” a constraint-provided indicator, displays the amount of inventory consumed. As a result, an identical amount of inventory is released. With rope, you can keep things moving and prevent items from building up.

What is a Constraint?

A constraint limits an organization’s capacity to fulfill its aims. Bottlenecks are another name for limitations, sometimes used in industrial activities. There are many different limitations, and they aren’t always mechanical in nature. Restrictions can be detected using a variety of methods. Here are some conditions that may be pervasive:

- The most prevalent cause is a lack of equipment, although a lack of staff or space can also be blamed.

- Policy

- Actions that are required or recommended.

- According to material provided to potential employees, “the traditional way of doing things at the office” may seem informal. Employee handbooks and collective bargaining agreements are examples.

- Ideas or habits of behavior have been entrenched due to a paradigm.

How Can the Theory of Constraints Help Your Organization?

When used correctly, the theory of constraints has the potential to change an organization’s entire way of thinking. It is used in various vocations, including healthcare and sales, in addition to the industrial business. Some of TOC’s particular benefits are as follows:

- Examining the company’s restrictions can help identify constrained growth.

- Changes are concentrated in areas with the most significant impact on earnings due to constraints.

- TOC paves the way for future enhancements.

- By keeping an eye out for potential problems, you may correctly predict the amount of time it will take to restore data in the event of an emergency.

Without further investment, the TOC shows an increase in available capacity. TOC encourages you to use what you already have rather than quickly purchasing new equipment or expanding your activities.

Putting it All Together

Some believe that a technique such as Six Sigma is just concerned with improving a specific aspect of an organization’s operations. While Six Sigma focuses on enhancing quality, it is possible quality is not the primary emphasis. Also, individual process improvement may harm an organization’s ability to fulfill customer expectations and deliver on time and under budget. All of the changes may not be fully covered by the cost reduction.

On the other hand, the TOC can also be a starting point for more complex circumstances.

Still, according to the theory of constraints, when discussing tools, it can be easy to forget the importance of the objective.